.png)

Brand Name: WELLPREN CPE IM series

WELLPREN IM SERIES is one of the most important impact modifiers for the plastics market. Compared to other impact modifiers such as AIM (Acrylic Impact Modifier), MBS, and ABS, CPE is more competitive in terms of comprehensive performance and pricing. Currently, CPE is increasingly preferred by customers and is expanding its share in the impact modifier market.

When an appropriate amount of WELLPREN® RESIN is added to PVC, PE, or PP plastic formulations, it not only significantly increases impact resistance but also greatly improves low-temperature performance, weatherability, weld strength, and other properties. WELLPREN® RESIN can be used as a replacement for acrylic impact modifiers or their blends with minor formulation adjustments, providing an optimal performance-to-cost solution.

WELLPREN® RESIN helps manufacturers and compounders meet increasing critical performance requirements and cost control needs.

Features of WELLPREN® RESIN

-

Excellent flexibility and good low-temperature impact strength

-

Compatible with products providing acrylic impact resistance

-

Superior compatibility with polymers such as PVC, PE, and ABS

-

Outstanding weather resistance

-

Excellent processability

-

Superior corner strength

-

High surface gloss

-

Good filler acceptance

-

Cost-effective

-

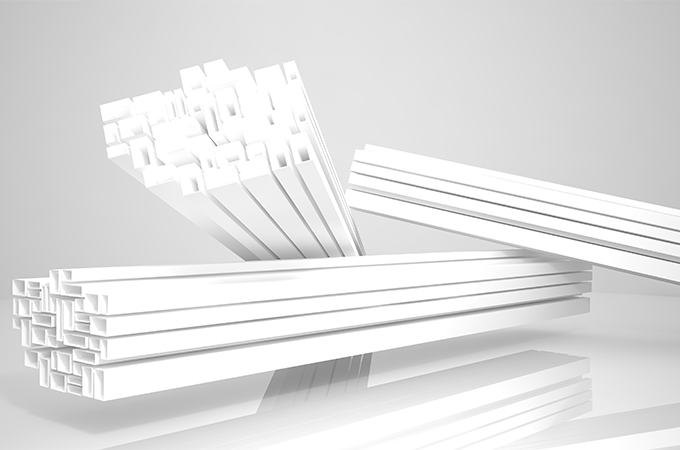

Impact Modifier for Rigid and Semi-Flexible Products: WELLPREN® RESIN is a high-performance, cost-effective impact modifier widely used in many rigid plastic products such as PVC profiles, pipes, pipe fittings, sheets, and siding. It significantly improves the impact resistance, low-temperature performance, weatherability, and weld strength of the final products.

-

Flame Retardant in ABS Applications: Due to its chlorine content, WELLPREN® RESIN has flame-retardant properties. It does not drip during burning and self-extinguishes after the flame is removed. These properties make CPE suitable as a component in flame-retardant ABS. Adding WELLPREN® RESIN to a flame-retardant ABS formulation not only reduces the need for large amounts of inorganic flame retardants that could negatively affect physical performance, but also contributes positively to the overall flame retardancy and significantly improves the impact strength of the final product (e.g., TVs, computers).

-

Soft Products: WELLPREN® RESIN, being a good elastomer, can be used directly in soft products. Since plasticizers are not required in soft product formulations using WELLPREN® RESIN, the resulting products have superior weatherability and long service life. This effectively prevents defects in traditional soft PVC products caused by plasticizer migration.

WELLPREN® IM Series Range

The standard WELLPREN® IM series includes seven types covering different molecular weights, chlorine content, and crystallinity. Custom grades can also be developed upon specific customer requests.

Key Variables in CPE Resins

1. Melt index, indicating the molecular weight of the CPE

2. Chlorine content

3. Viscosity

4. Fusion temperature

Contact Form